Lean

Manufacturing

Lean Manufacturing – As many companies have adopted the LEAN principles in their day-to-day operation, some business still need help defining these processes and procedures. Full Circle Machine Services can help identify many different ways to improve workflows, remove waste and further advance your business and the employees that work within them.

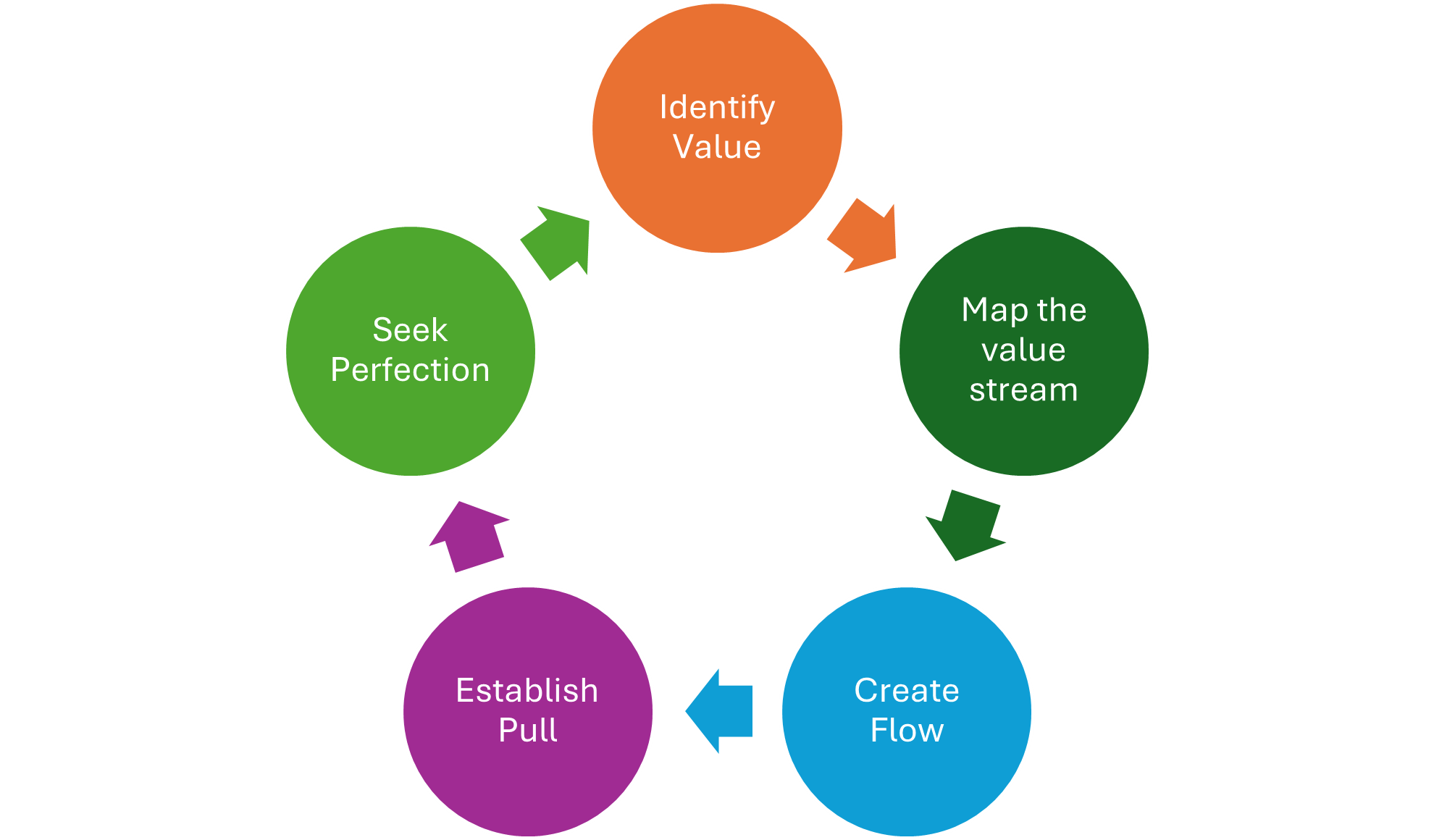

The five main principles of LEAN manufacturing:

Identify Value – The first principle, this doesn’t always have to be associated monetarily, finding value in other ways such as employees well being and the struggles they face day to day performing a task is a great way to identify value.

Map the Value Stream – The second Lean principle is mapping the value stream. In much simpler terms this process starts at the beginning of the product that is manufactured all the way to the disposal of said product. Identifying the different activities that are wasted in the process of making each product ensures the customer is getting exactly what they need, eliminating these unnecessary steps along the way and at the same time reducing the cost of the product or service.

Create Flow – In step three of Lean manufacturing principles, now you get to create the flow of your product from beginning to end. Since you have removed the waste in the previous step, now you need to create a smooth and efficient process for the product or service. The is where Full Circle can assist. Creating and building flow using custom designed workstations, conveyor systems, and automation are easy ways to vastly improve product flow. Automation doesn’t always mean a 6-axis robot, automation could be as simple as adding a barcode system, or an inventory control system.

Establish Pull – The fourth step of Lean principles is inventory control. Over stock of inventory, works in progress, or not having enough material are all ways of waste within a business. Eliminating these by just in time manufacturing may be a better way for some businesses but might not be a fit for all. Full Circle can help identify ways to help you through this process, its not one size fits all for Lean, it can be a blend of many different principles that help drive your business forward.

Seek Perfection – The most important step of all takes place after you have mastered the previous four. Seeking perfection, although this step in never complete and is always evolving, each company and its employees should always try to find ways to continually improve processes. Small steps taken everyday will eventually amount to large gains in not only production but also employees wellbeing.

Lean Manufacturing

In summary, lean manufacturing represents a transformative approach to production that prioritizes efficiency, quality, and customer satisfaction. By systematically identifying and eliminating waste, organizations can optimize their processes, reduce costs, and enhance overall productivity. This philosophy not only streamlines operations but also fosters a culture of continuous improvement, empowering employees at all levels to contribute to the organization’s success. Implementing lean principles provides a framework for businesses to respond more swiftly to market demands, adapt to changes, and innovate in their product offerings. As companies embrace lean methodologies, they often witness significant improvements in their operational metrics, including reduced lead times, higher inventory turnover, and enhanced product quality. Moreover, the focus on customer value ensures that the end product aligns closely with consumer needs, leading to increased satisfaction and loyalty. Ultimately, the journey toward lean manufacturing is not merely about adopting new practices; it is about reshaping the organizational mindset to prioritize efficiency and value creation. As industries continue to evolve, those who commit to lean principles will be better positioned to thrive in competitive markets, driving sustainable growth and fostering long-term success.